Introduction of Optical Splitters

What is Optical splitter ?

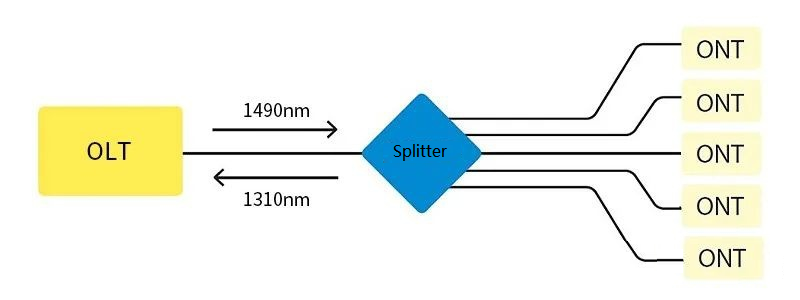

Optical splitter is an integrated waveguide optical power distribution device that serves to split optical signals. It is widely used in passive optical networks (such as EPON, GPON, BPON, FTTX, FTTH, etc.) and plays an important role.

Working Principle

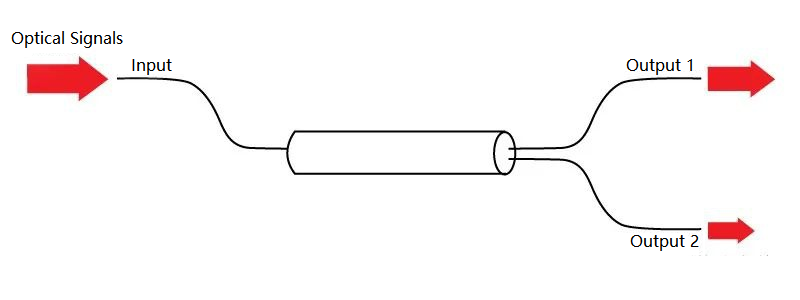

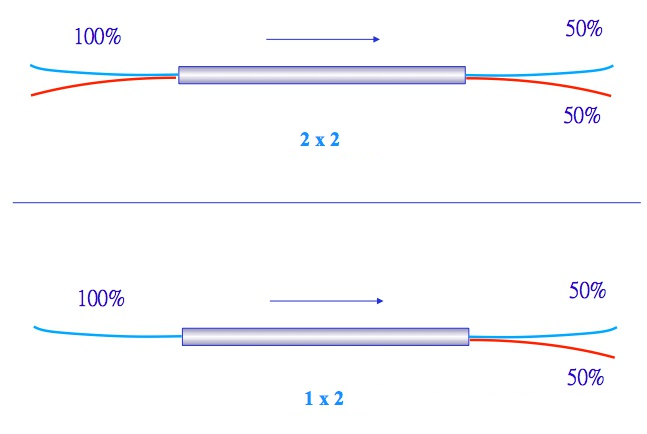

When an optical signal is transmitted in a single-mode fiber, the optical energy cannot be completely concentrated in the fiber core, and a small amount of optical energy is propagated close to the fiber cladding. In general, when the distance between the cores of two optical fibers is close enough, the optical signal transmitted in one optical fiber can enter the other optical fiber, that is, the optical signal can be redistributed in the two optical fibers, which is exactly the origin of the optical splitter.

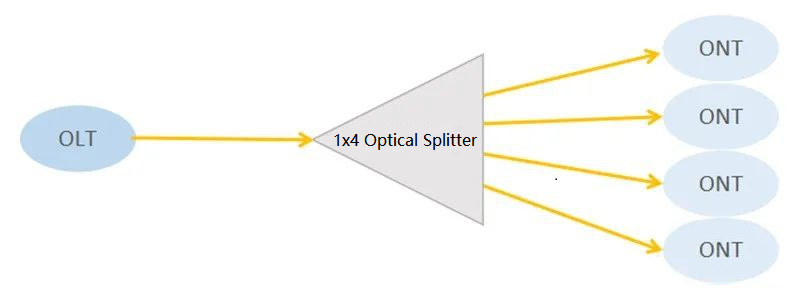

For example, a 1x4 optical splitter can distribute the optical signal in one optical fiber to four optical fibers in equal proportions. In fact, in simple terms, it is to distribute 1000Mbps bandwidth to four families equally, and each family can use a network with 250Mbps bandwidth.

Types of Optical Splitters

Fiber optic splitters are divided into two types according to its working principle: FBT splitter and PLC splitter.

What is PLC Splitter?

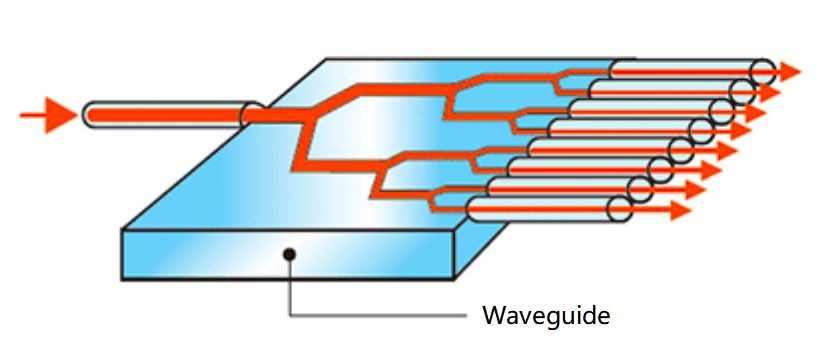

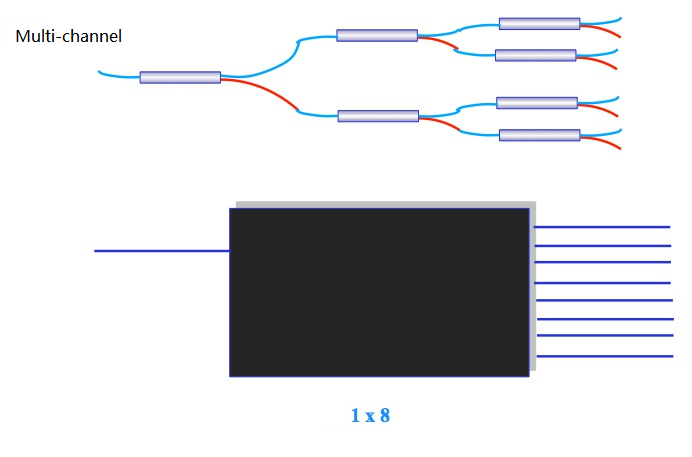

PLC splitter is based on planar light wave circuit technology. It consists of three layers: substrate, waveguide and cover. Waveguides play a key role in the splitting process that allows a specific percentage of light to pass through. So the signal can be divided equally. In addition, the PLC splitter has a variety of split ratios to choose from, including 1:4, 1:8, 1:16, 1:32, 1:64, etc.

What is FBT Splitter?

FBT splitter is based on traditional technology, which welds multiple optical fibers together from the side of the optical fiber. The fibers are aligned to specific positions and lengths by heating. Due to the fused optical fibers are quite fragile, so they are protected by glass tubes made of epoxy resin and silica powder. Then inner glass tube with stainless steel tube and seal with silicon. With the continuous development of technology, the quality of FBT separator is very good and can be applied in a cost-effective way.

FBT Splitter vs PLC Splitter

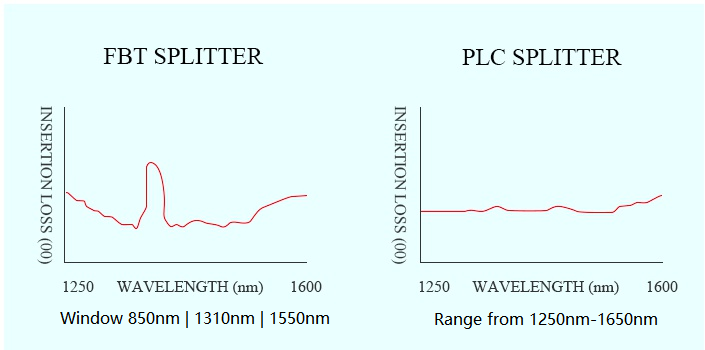

1.Working Wavelength

FBT splitter only supports three wavelengths at 850nm, 1310nm and 1550nm, which makes it unable to work at other wavelengths. PLC splitters can support wavelengths from 1260 to 1650nm. The wavelength tunable range makes the PLC splitter suitable for more applications.

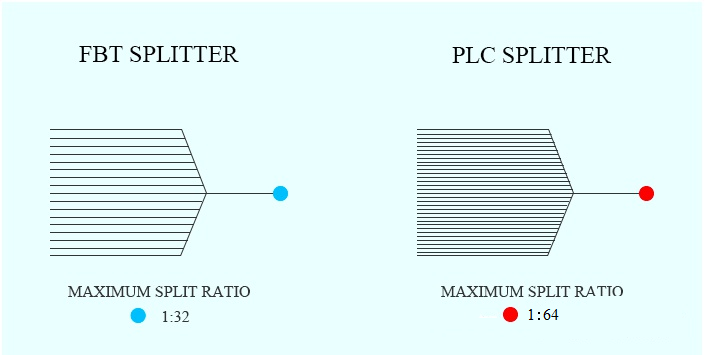

2.Splitting Ratio

The splitting ratio is determined by the input and output of the fiber optic splitter. The maximum split ratio of the FBT splitter is as high as 1:32, which means that one or two inputs can be divided into outputs of up to 32 optical fibers. However, the splitting ratio of the PLC splitter is up to 1:64 - one or two inputs with a maximum output of 64 fibers. In addition, FBT splitters are customizable, with special models of 1:3, 1:7, 1:11, etc. But the PLC splitter is not customizable. There are only 1:2, 1:4, 1 and other standard versions: 8, 1:16, 1:32 and so on.

3.Asymmetric Attenuation of Every Branch

The signal processed by the FBT splitter cannot be evenly distributed due to lack of signal management, which affects the transmission distance. But the PLC splitter can support the splitting ratio of all branches to be equal, which can ensure more stable optical transmission.

4.Failure Rate

FBT splitters are typically used in networks that require a splitter configuration is less than 4 splitters. The more shunts, the higher the failure rate. When its shunt ratio is greater than 1:8, it will lead to a higher failure rate. Therefore, FBT splitters are limited by the number of branches. However, the failure rate of PLC splitter is much lower.

5.Working Temperature

FBT splitters can work stably at temperatures from -5 to 75℃. PLC splitters can work in a temperature range from -40 to 85℃, with a relatively good performance in extreme climate regions.

6.Cost

Due to the complex manufacturing process of PLC splitter, its cost is generally higher than that of FBT splitter. FBT splitters can provide a cost-effective solution.

Guanglong S&T Zone, No.8 High-tech Industry Park Chaoyang Road, Guilin ,Guangxi, China

Guanglong S&T Zone, No.8 High-tech Industry Park Chaoyang Road, Guilin ,Guangxi, China  +86-133-4600-8527

+86-133-4600-8527  alan.shizz@glsun.com

alan.shizz@glsun.com