MEMS vs Mechanical Optical Switches: Which One Is Right for Your Network?

Why Optical Switch Type Matters in Fiber Networks

Optical switches keep fiber optic networks running smoothly, helping routes change without losing speed or data. When it comes to switching light signals, not all hardware works the same way. MEMS optical switches use tiny moving mirrors, while mechanical optical switches rely on simple moving parts.

Each type has its own pros and cons for speed, size, and reliability. Understanding how these two designs work can help you pick the right fit for your network—whether you want low cost, high performance, or something in between.

Understanding MEMS Optical Switches

MEMS optical switches are becoming popular in fiber optic networks as demands for compact and reliable switching grow. These switches use micro-scale technology, which lets them route light with high precision. Unlike basic mechanical switches, MEMS models can handle complex routes and offer faster operations in a tinier package.

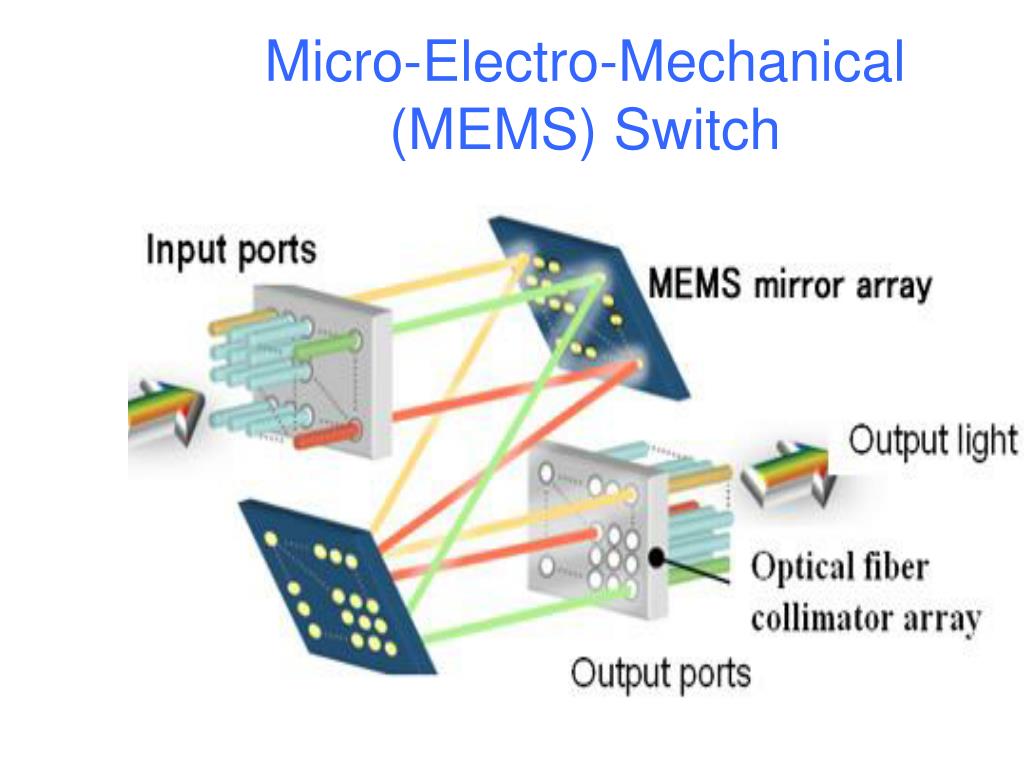

How MEMS Switches Work: The Role of Micro-Mirrors

MEMS stands for Micro-Electro-Mechanical Systems. A MEMS optical switch uses tiny mirrors that tilt or move to direct light beams from one fiber to another. Think of it like a small traffic controller, but for beams of light instead of cars. Each mirror shifts position electronically, steering the incoming signal toward the correct output.

How MEMS Switches Work: The Role of Micro-Mirrors:

Light enters the switch through an optical fiber.

Inside, electrical signals control minuscule mirrors.

The mirrors change angle quickly to reflect the light towards the desired path.

The beam reaches its correct exit port, all without converting light to electricity or vice versa.

This all-optical approach keeps signal loss low and speeds up switching. The process is nearly instant, with switches often reacting in milliseconds.

Design and Structure of MEMS Switches

The secret to MEMS switches lies in their design. These switches are built using microfabrication—the same process used for computer chips. This means they can pack lots of tiny moving mirrors into a small area.

Key parts of a MEMS optical switch:

MEMS mirrors: Made from silicon, these act as mini-traffic signs for light.

Actuators: Small electrical devices move the mirrors precisely.

Optical fibers: Carry light to and from the switch.

Support frame: Keeps everything steady, even at micro sizes.

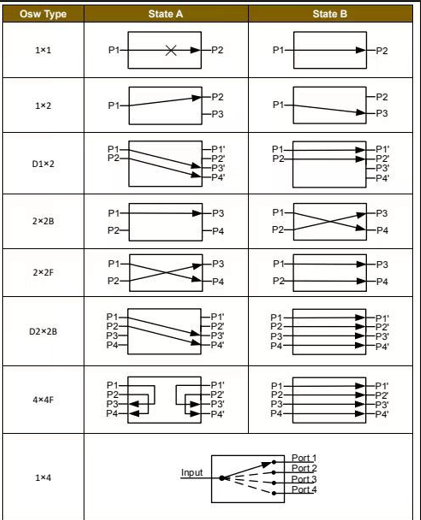

You can find MEMS switches in both 1xN (one input, many outputs) and NxN (many inputs and outputs) setups. Their compact size saves rack space and allows for higher channel density compared to mechanical switches.

Advantages and Limitations of MEMS Switches

Like any type of technology, MEMS optical switches come with strong points as well as trade-offs.

Advantages:

Small size: MEMS switches fit more channels in less space.

Quick switching: Movements happen in a few milliseconds.

Stable performance: The all-optical path means less signal loss.

Scalability: Easy to expand into larger, more complex networks.

Remote control: Switching happens through electrical signals, not manual levers.

Limitations:

Complex manufacturing: Building at the micro-scale requires special tools and skills.

Cost: More advanced than simple mechanical switches, sometimes costing more upfront.

Environmental sensitivity: Extreme temperatures or dust can affect tiny moving parts.

Limited repair: If a single mirror fails, fixing it might mean replacing the whole chip

MEMS optical switches deliver speed, density, and reliability, but also rely on precise engineering. This makes them a strong choice for modern networks needing fast and flexible signal routing.

Exploring Mechanical Optical Switches

Mechanical optical switches are the classic choice for controlling light paths in fiber optic networks. Unlike MEMS switches, they rely on straightforward moving parts to physically redirect beams of light. These switches offer a cost-effective and robust option when budgets are tight, or when you just need something simple that works.

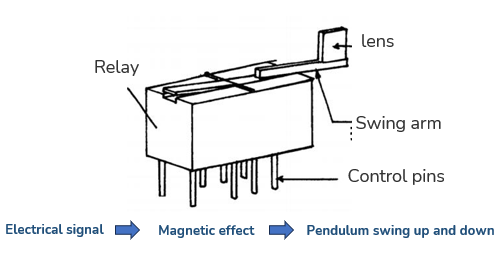

How Mechanical Switches Redirect Light

Mechanical optical switches work by moving tiny mirrors or prisms into place to steer light from one fiber to another. When you trigger the switch—either manually or electronically—a mechanical actuator slides or rotates a component inside. This movement shifts the light path, allowing the signal to jump from the input fiber to the selected output.

This process is direct and clear:

An actuator receives a signal to change the light’s direction.

The moving part (often a mirror, prism, or shutter) lines up with the incoming beam.

The light is physically redirected to the desired optical fiber.

Nothing converts or transforms the signal in between. The entire signal stays as light from start to finish.

Design and Components of Mechanical Switches

Core Components of Mechanical Switches

At the heart of every mechanical optical switch are some basic yet reliable components. While there are design variations, most switches include these main parts:

Optical Fibers: These carry the light into and out of the switch.

Moving Elements: Usually mirrors, prisms, or shutters. These shift the beam toward different outputs.

Actuators: Tiny motors or mechanical levers that move the mirrors or shutters into place.

Frame or Housing: Holds everything steady and protects the moving parts from dust and physical damage.

Control Electronics: Optional, for remotely managing actuator movement.

Some switches are tiny, fitting on a small board for single-channel control. Others have larger arrays for handling multiple inputs and outputs. The design is straightforward, which helps keep costs down and maintenance simple.

Strengths and Weaknesses of Mechanical Switches

Mechanical switches come with their own set of advantages and trade-offs. Here’s a breakdown of what they offer:

Strengths:

Simple Design: Fewer moving parts mean less to go wrong, making them reliable.

Low Cost: Budget-friendly for basic routing needs.

Direct Light Path: Minimal signal loss, since the light travels through air or glass without extra stops.

Easy Maintenance: Most repairs involve swapping out basic parts, not entire chips.

Good Isolation: Physical separation keeps signals clean and interference low.

Weaknesses:

Slower Switching: Movement takes more time than micro-mirrors; milliseconds to seconds, not instant.

Wear and Tear: Moving parts can degrade over time, leading to more frequent replacements in heavy-use settings.

Bulkier Size: Larger footprints compared to compact MEMS switches, especially in multi-channel setups.

Manual Handling: Some models require manual operation, not great for remote or automated networks.

These switches are a practical solution for many basic routing applications. However, if you need high-speed, high-density switching, you'll likely find their pace and size limiting. For simpler jobs, though, their reliability and low cost often make them the top choice.

Guanglong S&T Zone, No.8 High-tech Industry Park Chaoyang Road, Guilin ,Guangxi, China

Guanglong S&T Zone, No.8 High-tech Industry Park Chaoyang Road, Guilin ,Guangxi, China  +86-133-4600-8527

+86-133-4600-8527  alan.shizz@glsun.com

alan.shizz@glsun.com